Loading asset information.

Loading asset information.

Documentation: Light Object Product Page

Additional Documentation: Laser

Network Information

MAC (cabled):

IP address: 192.168.99.220 SM: 255.255.255.0

No Gateway

Program Information

How-to’s, history, maintenance guides and more can be found via the main Laser Page. It is very important to follow all guidelines regarding startup/shutdown and filter care instructions on each use.

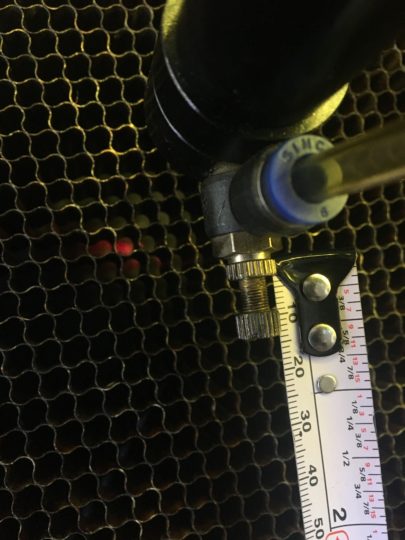

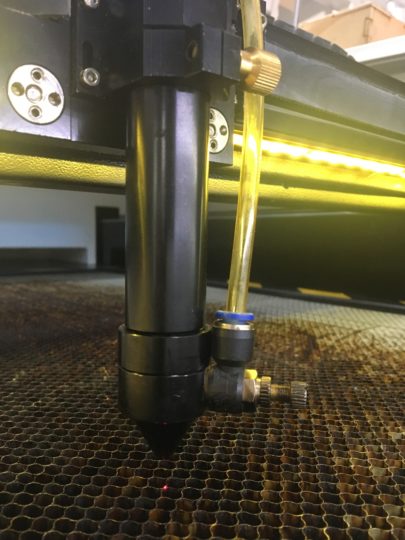

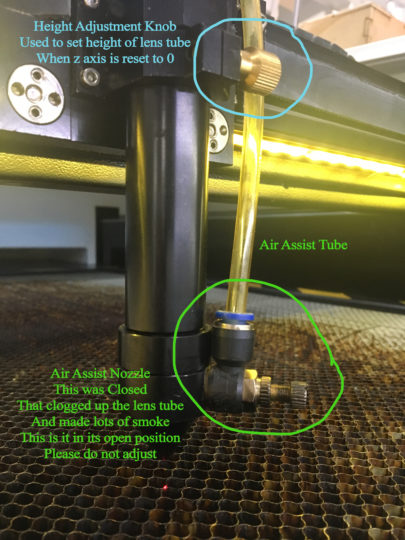

Air Assist Configuration

Please note the photos below show how the air assist needs to be configured.

Maintenance Logs

Status Logs

Loading asset logs.

Loading asset logs.

1/17/20

Filter box not drawing smoke from the laser. Machine down.

Anemometer readings:

- Front intake vents, lid closed = 0, 178 no filter

- Center honeycomb, top = 3.3. virtually no fan movement

- Center vent under bed = 985 – I think the baseline read was not over the vent, I got a 0 when I just held it under the bed)

- Intake at filter = 1790

- Outflow at filter = 957 (after repositioning accordion filter was able to get it to 1650)

- intake for shop based exhaust = 1037

there are significant variances especially in the outflow at the filter

Conclusion… The filter box filter was very clogged. Supposedly re-usable. Need washing instructions.

Actions taken: Put the laser on old-fashioned ventilation, cleaned optics.

Build Logs

2/20/20

Anemometer readings after cleaning the blower fan with a brand new filter. These readings pass the draw test.

2300 on the blower side

500 on the laser side

2500 the vent under the honeycomb

1/1/20 – Crafty

Working on setting up the big filter box.

Filter box output connected. Support needs to be moved. Needs to be replaced with proper vent run sooner rather than later.

Anemometer readings:

- Front intake vents, lid closed = 372

- Center honeycomb, top = 213

- Center vent under bed = 349 (measurement really hard to take, maybe need to make a stand off)

- Intake at filter = Still need to get

- Outflow at filter = 1579 (very very blowie)

- intake for shop based exhaust = 1357 (very very vacuumy)

12/31/19 – Crafty

Marco came and swapped out the smaller filter box with a large 220v filter box. Replaced HV power supply as the spontaneous firing was indicative of a busted diode in the HVPS. Lubricated rails.

Hi! I took the Laser Basics and Certification class two Saturdays ago, but have not taken the post-class exam yet. Where is the link to that?

The link was on the laser page of our website: https://www.acemakerspace.org/laser-101-knowledge-check/