About lathe tools and accessories

Overview

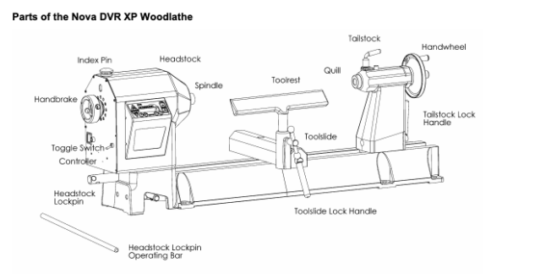

Wood is secured in between the headstock and tailstock. The motor then spins the wood while tools, resting against the tool rest, shape and cut it.

Two types of turning

Spindle Work — Wood is wedged between headstock and tailstock. You can shape and cut the side of the wood but you can’t cut the ends because the tailstock is in the way.

Face Plate Work — Wood is only secured to the headstock by using screw or a “chuck.” This leaves the tailstock end free so that you can carve out wood and make bowls or other vessels.

Impacting Factors

Speed — Speed affects the amount of vibration and development of cuts. Its impact can be imagined easily, if you’re using the parting tool and the lathe is at 750 RPM, then it would cut into the wood half as far as if the lathe was at 1500 RPM. Ace’s lathe can turn the wood at 100-3500 RPM (in 5 RPM increments). A good rule of thumb is, “the thicker/wider the stock (wood), the lower the speed). So a narrow piece of wood, 2-½” thickness or thinner, can be turned at 1500-2000 RPM while thicker pieces of wood should be turned at about half that speed. Generally, start with a lower speed (750 RPM) and work your way up as you begin shaping and adding detail.

Tool Sharpness — Keep your tools sharp! Sharp tools make things easier. You can use grinding stones or diamond honing pads, there are lots of ways, just ask the friendly Ace community on slack to see what they use.

Tools: