Loading asset information.

Loading asset information.

Make/Model: Saw Trax 1064

Manual: Saw Trax Panel Saw – User Manual | Makita Saw Manual (actual saw on the unit)

Panel saw basics

What does a panel saw do?

The panel saw can cut full sheets of plywood: up to 48” vertically and unlimited length horizontally.

- Max cross-cut: 64″

- Max rip: technically unlimited, but hard limit is what will fit into the shop. Saw rotates 90 degrees to facilitate this type of cut

- Max thickness: 1.75″

- Blade size: 7.25″

- Installed Options: laser line, lower frame dust collection port

- Materials it can cut: wood, wood composites (plywood, MDF), hard board, laminates, melamine, some foams and other soft materials

Use, rules, and safety

- Clamping is not required when using this saw

- Always use dust collection

- Open the dust collection gate and turn on the cyclone

- Check the cyclone can before you begin. What to do if a previous user left dust behind.

- Use your free hand to press the workpiece against the frame

- There is a momentary switch to turn on a laser guide for vertical cuts

- Don’t rest your hands on the saw support rails

Crosscuts (vertical cut)

- Ensure that the saw is locked with the silver motor guard in the vertical position

- If it is not, pull the two black pins towards you, and rotate the saw counter-clockwise until it locks into place

- Line up your cut

- Using the horizontal rules, align your piece to the ruler on the side of the workpiece which you wish to keep. For example, assume you have a 4′ x 8′ sheet of plywood, and want to cut off a 2′ piece from the left side of the sheet. Align the left side of your sheet to the 2′ mark on the ruler on the left side of the saw.

- If you were to use the right side in this example and align to the 6′ mark to give yourself a 2′ piece on the left, the piece you want may be smaller than that because of the saw kerf.

- Pull the saw trigger and move the sled all the way to the bottom of the frame

- Release the trigger and allow the saw to come to a complete stop

- You may then move the saw sled

- moving the sled prior to the saw stopping may damage your piece.

Rip cuts (horizontal cut)

-

- Ensure that the saw is locked with the silver motor guard in the horizontal position

- If it is not, pull the two black pins towards you, and rotate the saw clockwise until it locks into place

- Line up your cut

- Using the vertical ruler, align the flat part of the upper brass indicator to the desired height and lock the saw sled to the rails using the black knobs.

- Make your cut

- Use the trigger lock to activate the saw and keep it running

- Push your workpiece through the panel saw from left until it has cut to the desired length

- Remove the trigger lock, and allow the blade to come to a complete stop

- When completed, return the saw to the vertical orientation

Parts of the saw

The two black knobs in the above photo are spring loaded pins, pulling them towards you unlocks the saw housing, allowing it rotate. In this photo, the saw is configured for a cross cut

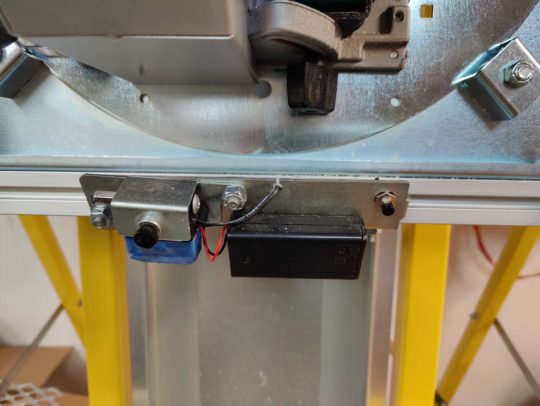

This is a laser line to help you align your cut. The black box is a battery compartment, the small black button to the right of it turns on the laser. This is a momentary switch, the laser is only active while you are pressing this button. It is not mean to remain on while cutting.

The saw sled is equipped with locks. The black knob in this photo is the right track lock, there is a matching lock on the left. Ensure that these are unlocked before making a cut.

[Photo of the horizontal rulers to be added]

There are horizontal rulers on the lower part of the saw. Each ruler is calibrated such that its 0 meets the outside of the saw blade on that side. Essentially the kerf does not exist on these rulers.

[Photo of the Vertical ruler and measure indicator to be added]

There is a vertical ruler near the left saw track to help you line up a horizontal “rip” cut. To select the proper height, use the upper brass indicator. This one aligns with the saw blade.

Maintenance

- Keep free of dust, including workpiece support rollers

- Check power cord for fraying or breakage

- Ensure that dust collection hoses are in good condition and attached to the saw, lower frame port and blast gate

- Use appropriate blade for the material you are cutting

- Periodically sharpen or replace blade

- Periodically apply silicone spray to the spinning insert, guide tube and roller bearings

- If parts of the frame become scratched, touch up with paint to prevent rusting or corrosion

Status

Loading asset logs.

Loading asset logs.