Loading asset information.

Loading asset information.

Make/Model: WEN 4225

Documentation: https://wenproducts.com/collections/drill-presses/products/15-inch-variable-speed-drill-press-4225#shopify-product-reviews

Drill press basics

What does a drill press do?

A drill press spins a bit precisely in one spot (X-Y axis) and allows you to easily adjust the pressure (Z axis).

- 4-inch stroke makes drilling through 4×4 boards easier than ever

- Adjust the variable speed anywhere from 280 RPM to 3300 RPM

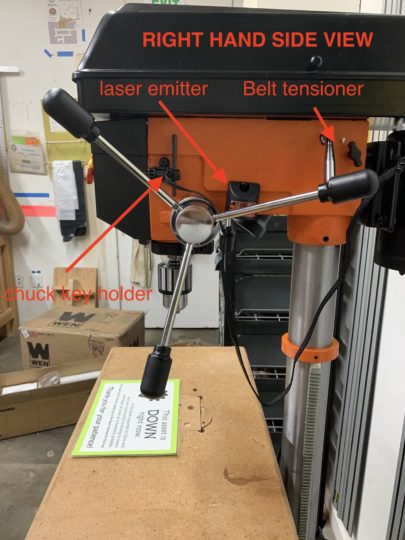

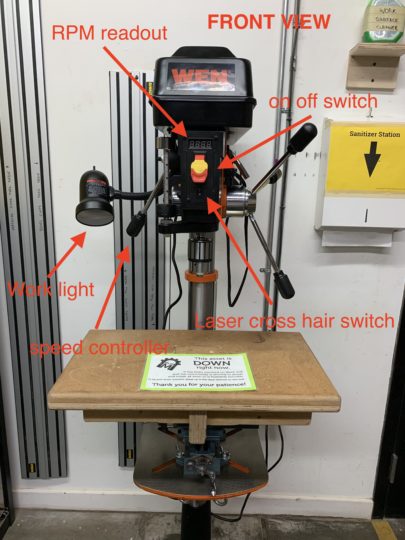

- Includes a built-in work light, a precision laser, a 1/16 to 5/8 inch chuck, and onboard chuck key storage

- 12-inch by 12-inch cast iron work table pivots up to 45 degrees in both directions

- Backed by a 2-year warranty, a friendly customer service line and a nationwide network of skilled technicians

Use, rules, and safety

- The drill press is not on the vacuum system – use a shop vac to clean up during and after use.

- Check and empty the shop vac before and after use.

- Unplug the drill press after use and when changing bits

- There is a speed readout which must be switched on to operate

- Only change the speed with the speed control lever when the drill press is on! This is signposted on the machine but please try to avoid this as it can damage drive pulleys and belts.

- Let the drill press stabilize on a speed before you begin drilling

- Adjust the table height after releasing the table lock. Lock the table when it is not being adjusted.

- You can rotate the table completely out of the way if you want to drill into the top of something large or tall.

- No freehand drilling on the drill press. Everything must be clamped, ideally in two locations. The left side of the column counts as one clamp if your stock is in contact with it.

- You cannot drill holes deeper than about half the maximum Z-axis movement of the drill press, because the bit takes ½ the range of motion and the hole takes the other ½/. Use a hand drill or the lathe for deeper holes.

- Do not adjust the table angle. Clamp the workpiece at an angle instead.

- You must tighten a keyed chuck in two positions to allow the jaws to equalize pressure on the bit so it doesn’t wobble or loosen during use.

- Do not overtighten the chuck – not all of your hand strength is needed. It is better for the bit to slip than to break.

Drill speed

Using the correct speed and pressure yields the best results and prevents breaking bits.

- There are two speed ranges. You must switch the position of the belt inside the head to switch between the two speed ranges.

- The pressure you apply can make any speed wrong.

- A badly wrong speed cannot be made right by varying the pressure.

- The speed chart on the side of the drill press is “Wrong”: it is generally too fast

Drill bits

Drill bits come in different sizes and styles with different capabilities

- Twist drills make smooth holes in flat surfaces of most materials – must be perpendicular to the workpiece

- Forstner bits make smooth whole or partial holes with flat bottoms in wood at any angle

- Spade bits make rough holes quickly – better for running romex than for woodworking

- Drill index has sizes organized by small increments

Drill press parts

Logs

Loading asset logs.

Loading asset logs.